Screen Printing Inks :

Sustainable Inks

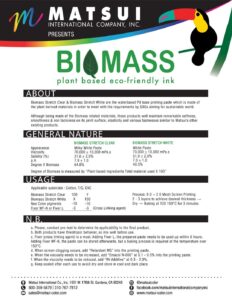

Biomass

Biomass Stretch Clear and Biomass Stretch White are water-based PU or Acrylic-based printing pastes crafted from plant-derived materials, aligning with the goals of the Sustainable Development Goals (SDGs) for a more sustainable world.

Technical Data Sheet

FEATURES

Despite being composed of Biomass-related materials, these products effectively retain impressive softness, smoothness, non-tackiness on their print surface, elasticity, and various fastness qualities, mirroring Matsui’s other established products.

SPECIAL RECOMMENDATIONS

- Please, conduct pre-test to determine its applicability to the final product.

- Both products have thixotropic behavior, so mix well before use.

- Fixer (cross linking agent) is a must. Adding Fixer L, the prepared paste needs to be used up within 6 hours. Adding Fixer WF-N, the paste can be stored afterwards, but a baking process is required at the temperature over 150°C.

- When screen clogging occurs, add “Retardant MG” into the printing paste.

- When the viscosity needs to be increased, add “Emacol R-600” at 0.1 – 0.5% into the printing paste.

- When the viscosity needs to be reduced, add “RV Additive” at 0.3 – 2.0%. g. Keep sealed after each use to avoid dry and store in cool and dark place.