Screen Printing Inks :

Water Resistant Special Effects Inks

PRODUCTS FEATURES

- Easy to mix and print

- Is “PVC Free” and environmentally safe

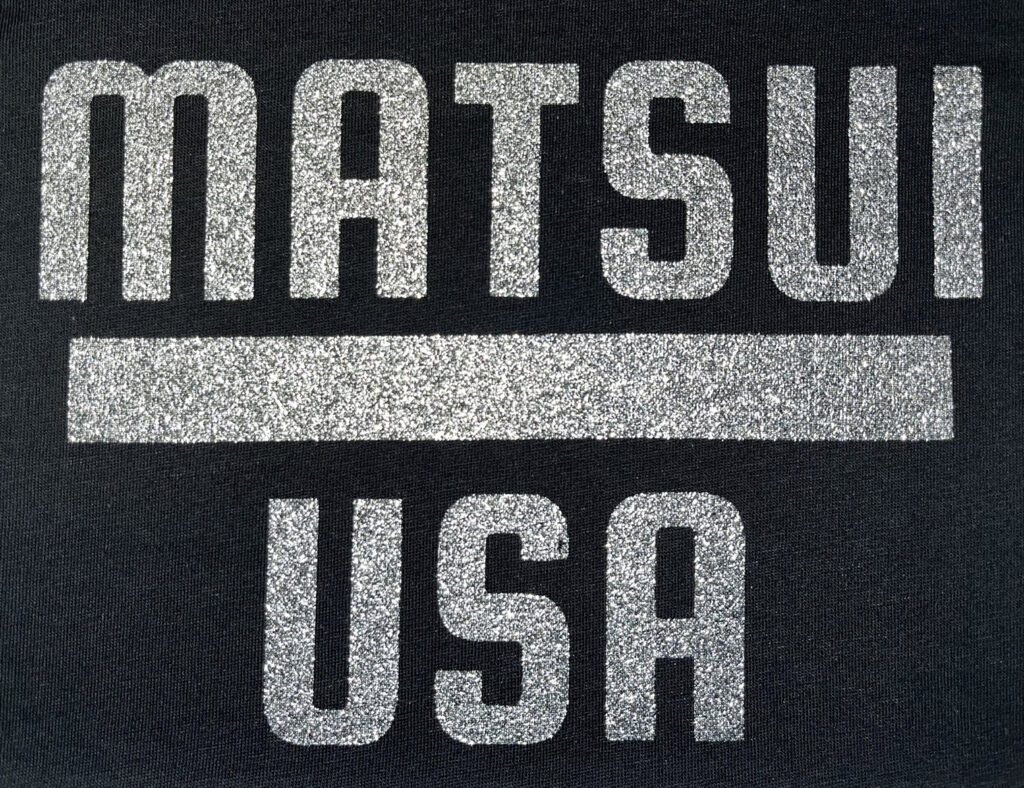

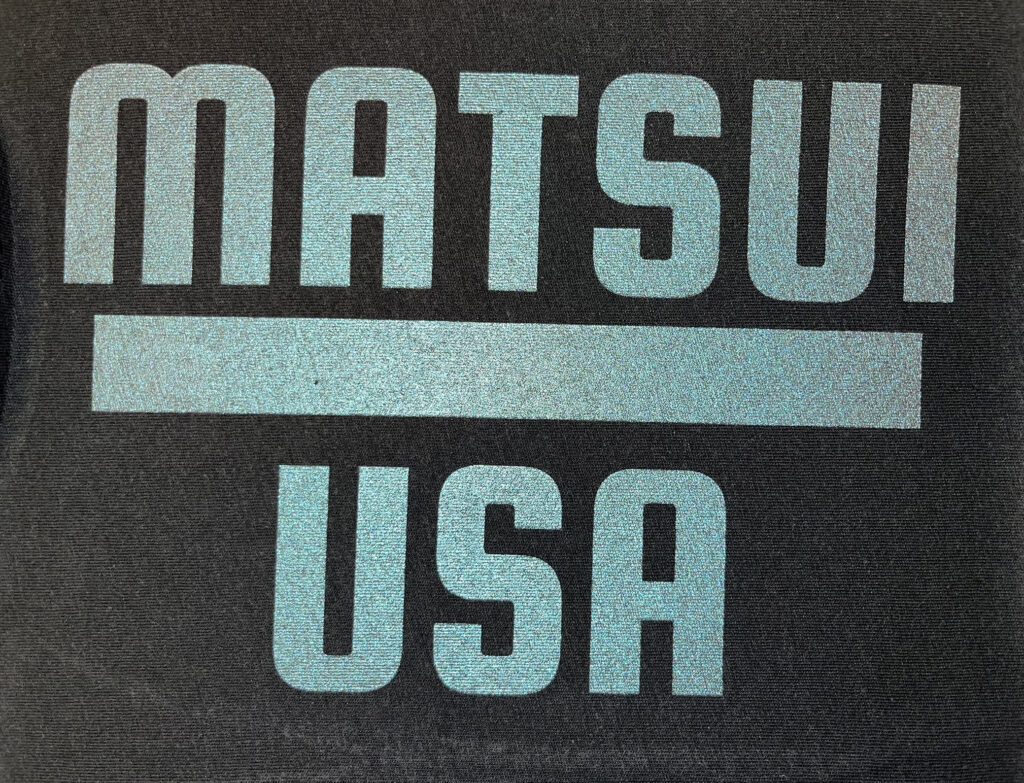

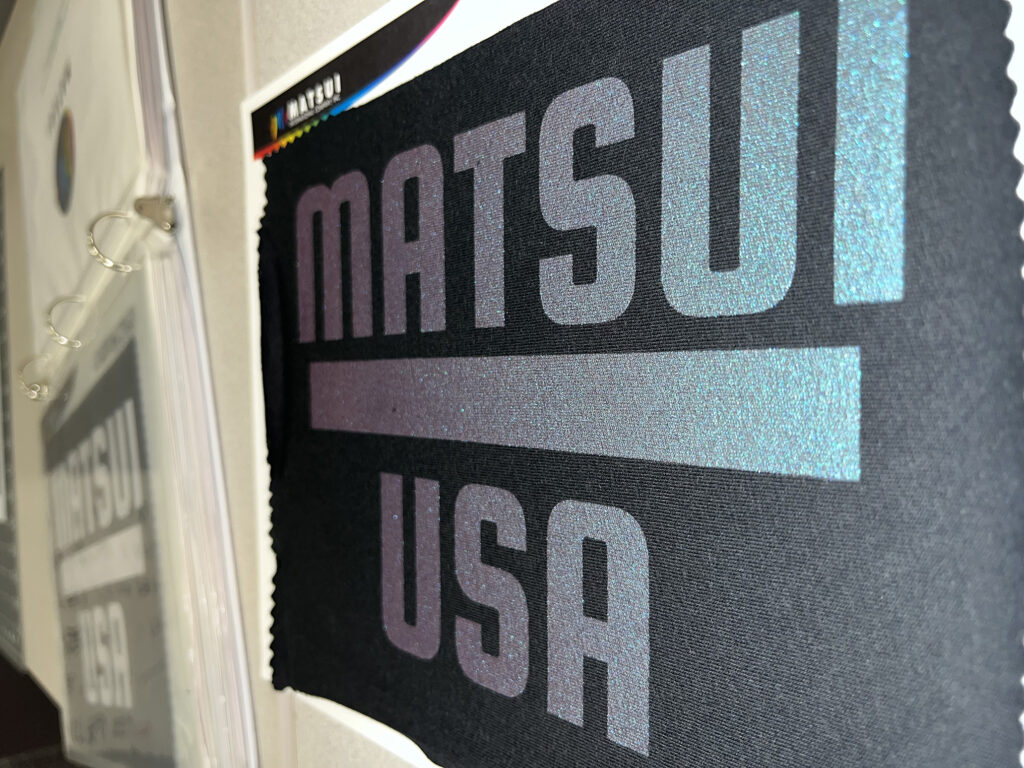

Silver/Gold Shimmer 620

Silver/Gold Shimmer 620 serves as a silver/gold metallic base suitable for standalone shimmer applications or can be combined with “Neo Pigments” to produce a variety of colors.

FEATURES

- Create multiple colors when tinted with Neo Pigments

- Excellent printability with no viscosity modifications

- Extremely soft hand feel that PVC inks cannot achieve

SPECIAL RECOMMENDATIONS

Silver/Gold Shimmer 620 must be blended in clean vessels using clean mixing blades and utensils. Any contamination from alternative ink sources or non-approved additives could lead to undesired outcomes.

- Silver/Gold Shimmer 620 can be dry cleaned or ironed

- Use Retarder MG 1-5% to help with open time in the screen

- Use Fixer WF-N 1-5% to help with fastness

- Use Softener MG 1-4% to help penetrate in to the garment

- Use Thickener B .25-1% to help thicken the ink

- Use RV Additive 1- 3% to reduce viscosity

Pearl Binder 301

Pearl Binder 301 is a pearlescent base that can be utilized independently or mixed with “Neo Pigments” to generate a variety of colors.

FEATURES

- Create multiple colors when tinted with Neo Pigments

- Excellent printability with no viscosity modifications

- Extremely soft hand feel that PVC inks cannot achieve

SPECIAL RECOMMENDATIONS

Pearl Binder 301 is to be blended in pristine vessels using clean mixing blades and utensils. The presence of any contaminants from other ink sources or non-approved additives could result in Pearl Binder 301 testing positive for restricted PVCs.

- Pearl Binder 301 can be dry cleaned or ironed

- Use Retarder MG 1 – 5% to help with open time in the screen

- Use Fixer WF – N 1 – 5% to help with wash fastness

- Use Softener MG 1- 4% to help penetrate in to the garment

- Use Thickener B .25 – 1% to help thicken the ink

- Use RV Additive 1 – 3% to reduce viscosity

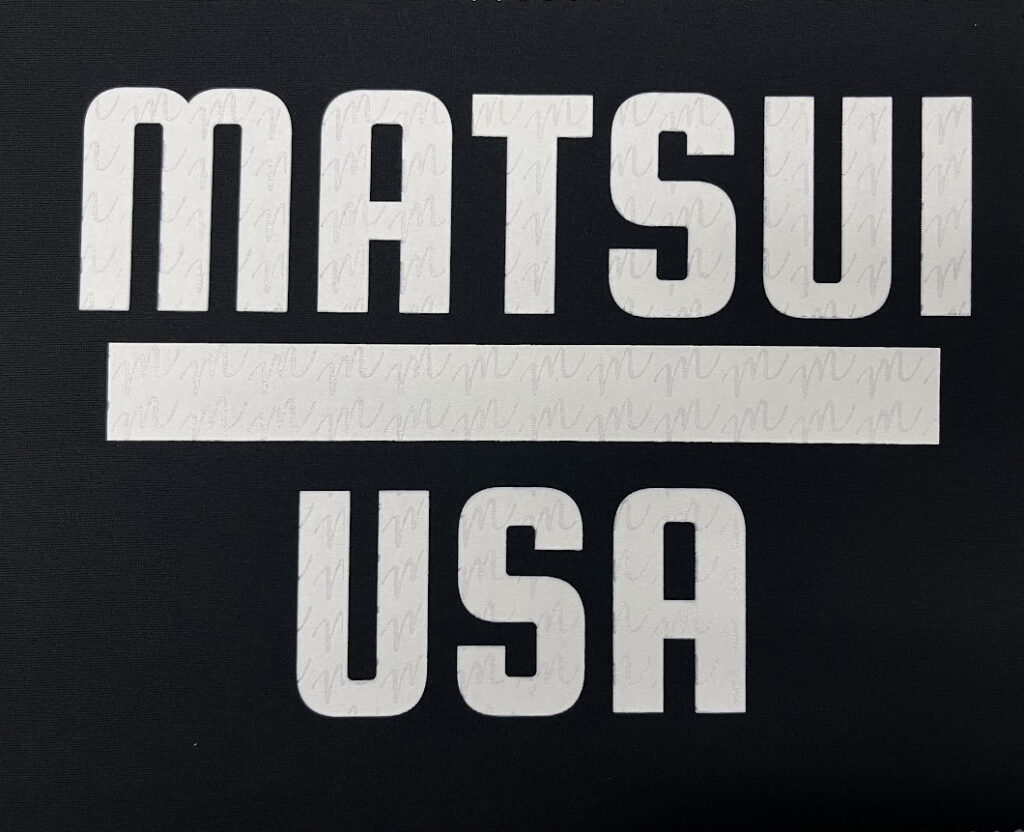

Glitter Base 301

Glitter Base 301 is formulated to permeate fabric, revealing exposed glitter flakes and achieving a dry glitter effect.

FEATURES

- Create color shades by tinting with “Neo Pigments” at a minimal level

- Add up to 25% of dry glitter flakes and mix well

- Excellent printability with no viscosity modifications

- Provides excellent adhesion to the flakes to provide minimal flake off

SPECIAL RECOMMENDATIONS

Glitter Base 301 must be blended in pristine vessels using clean mixing blades and utensils. Any introduction of contaminants from other ink sources or non-approved additives could lead to Glitter Base 301 testing positive for restricted PVCs.

- Use Retarder MG 1-5% to help with open time in the screen (Recommended)

- Use Fixer WF-N 1-5% to help with wash fastness (Recommended)

- Use Softener MG 1-4% to help penetrate in to the garment (Optional)

- Use Fixer L 1-3% to help hold powder during wash (Optional)

- Use Thickener B .25-1% to help thicken the ink (Optional)

- Use RV Additive 1-3% to reduce viscosity (Optional)

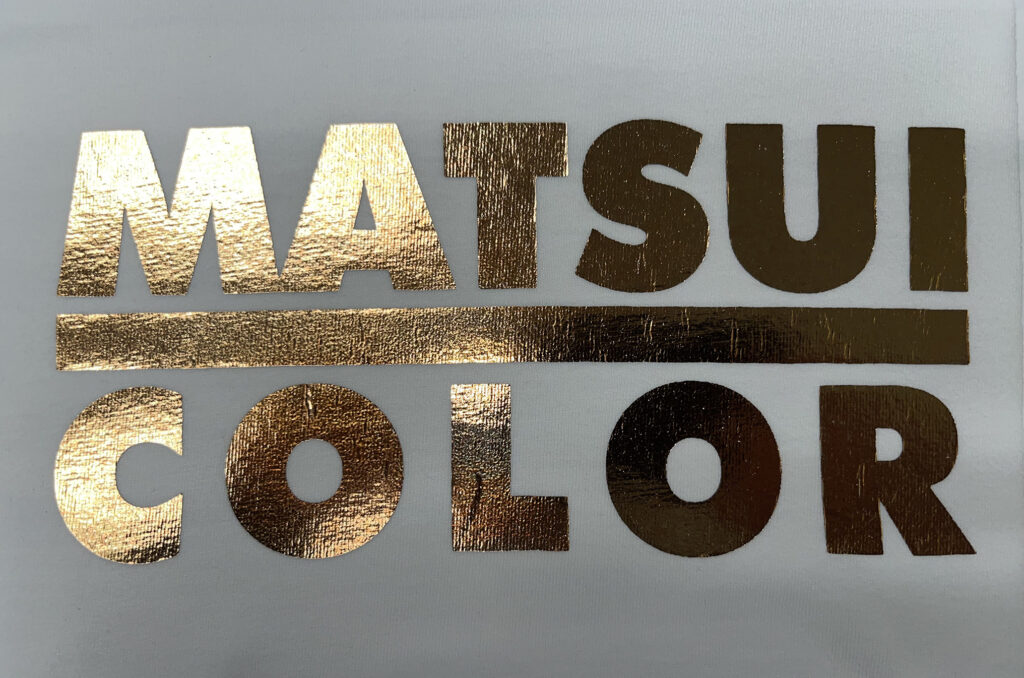

Foil Adhesive TFG 301

Foil Adhesive TFG 301 serves as a foundational adhesive for flock sheets, foil transfer, and Reflectalite SK sheets, showcasing outstanding adhesion qualities. It is suitable for printing on a wide range of textile fabrics where a printable adhesive is required.

FEATURES

- Can be tinted with “Neo Pigments ” to match embellishment color

- Excellent printability with no viscosity modifications

- Extremely soft hand feel that PVC inks cannot achieve

- Great for adhering fabric together

- Adhere flock sheets, foil and Reflectalite sheets to fabric

SPECIAL RECOMMENDATIONS

Foil Adhesive TFG 301 must be blended in pristine containers using clean mixing blades and utensils. Any introduction of contaminants from alternative ink sources or approved additives may result in a positive test for restricted PVCs in Foil Adhesive TFG 301.

- Use Retarder MG 1-5% to help with open time in the screen

- Use Thickener B .25-1% to help thicken the ink

Foil Blocker 301

Foil Blocker 301 is an anti-foil base designed to prevent foil from adhering to the intended print area. Apply Foil Blocker 301 in the specific region where you wish to avoid foil adhesion.

FEATURES

- Foil will resist to stick in areas where printed

- Excellent printability with no viscosity modifications

- Extremely soft hand feel that PVC inks cannot achieve

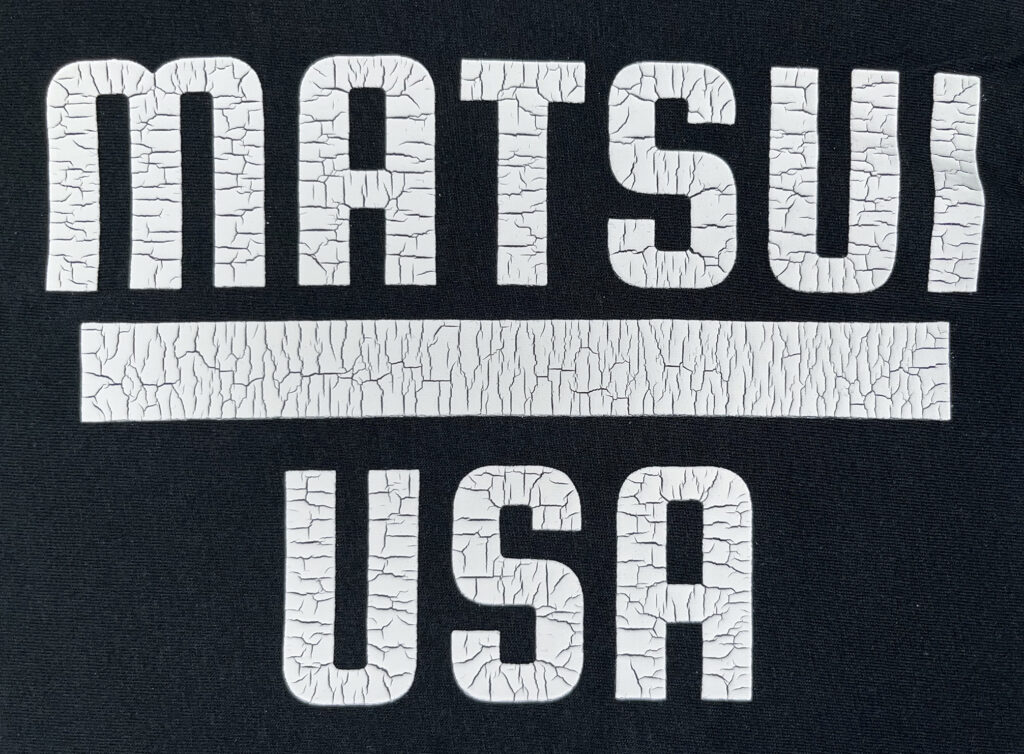

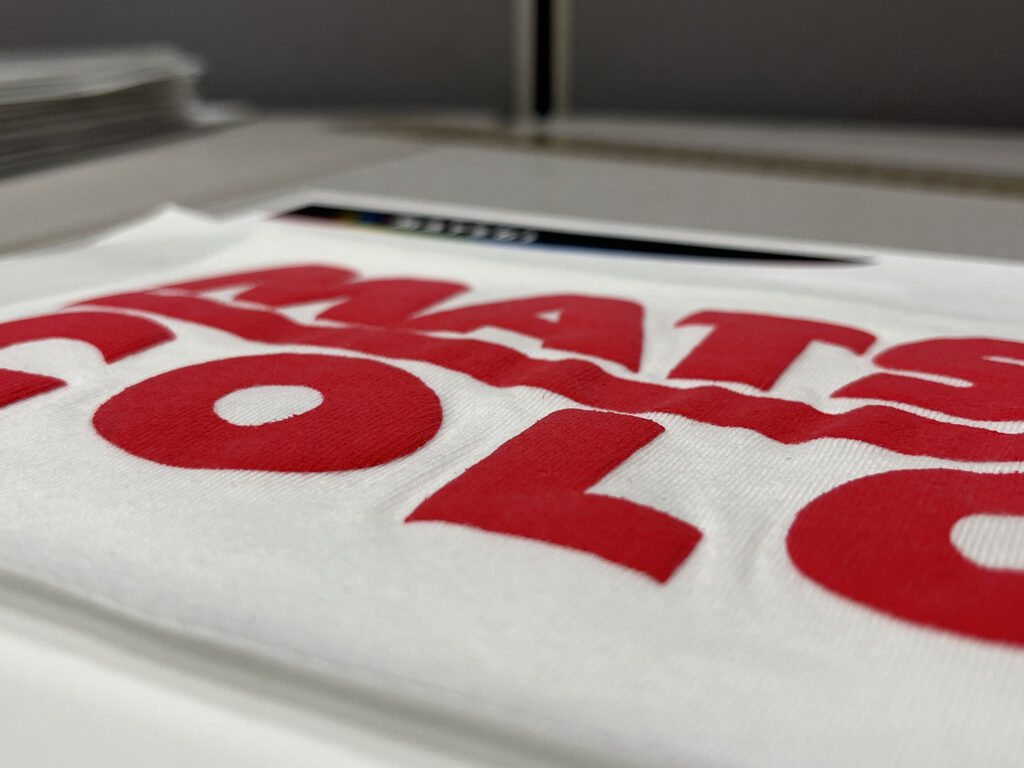

Crack Base

Binder CB/Crack Base is a semi-opaque foundation that produces a distinctive weathered crack effect.

FEATURES

- Can be tinted with “Neo Pigments ” to create vivid colors

- Can be printed on top of white underlay to accentuate cracks

- Excellent printability with no viscosity modifications

- Thicker ink deposit is recommended for best results

SPECIAL RECOMMENDATIONS

“Blend Binder Base/Crack Base in uncontaminated containers using clean mixing blades and utensils. The presence of contaminants from other ink sources or unauthorized additives may lead to a positive test for restricted PVCs in Binder

“

- Use Retarder MG 1-5% to help with open time in the screen

- Use Fixer WF-N 1-5% to help with wash fastness

- Use Softener MG 1-4% to help penetrate in to the garment

- Use Thickener B .25-1% to help thicken the ink

- Use RV Additive 1- 3% to reduce viscosity

Crack Base HO

Crack Binder 812/Crack Base HO is a highly opaque foundation that generates a distinctive weathered crack effect.

FEATURES

- Can be tinted with “Neo Pigments ” to create opaque colors

- Should be printed on top of underlay to accentuate cracks

- Excellent printability with no viscosity modifications

- Thicker ink deposit is recommended for best results

SPECIAL RECOMMENDATIONS

Mix Crack Binder 812/Crack Base HO in pristine containers using clean mixing blades and utensils. The presence of contaminants from other ink sources or unauthorized additives may result in a positive test for restricted PVCs in Crack Binder 812/Crack Base HO.

- Use Retarder MG 1-5% to help with open time in the screen

- Use Fixer WF-N 1-5% to help with wash fastness

- Use Softener MG 1-4% to help penetrate in to the garment

- Use Thickener B .25-1% to help thicken the ink

- Use RV Additive 1- 3% to reduce viscosity

Phantom Clear

Phantom Clear is an invisible ink specially formulated to seamlessly blend with colored fabrics that intensify in hue when exposed to moisture. The unique quality of Phantom Clear allows the printed image to remain concealed until the surrounding fabric darkens with moisture, unveiling the hidden design.

FEATURES

- Excellent printability with no viscosity modifications

- Extremely soft hand feel that PVC inks cannot achieve/li>

SPECIAL RECOMMENDATIONS

Blend Phantom Clear in uncontaminated vessels using clean mixing blades and utensils. The introduction of contaminants from other ink sources or unauthorized additives may result in a positive test for restricted PVCs in Phantom Clear.

- Phantom Clear can be dry cleaned or ironed

- Use Retarder MG 1-5% to help with open time in the screen

- Use Fixer WF-N 1-5% to help with wash fastness

- Use Softener MG 1-4% to help penetrate in to the garment

- Use Thickener B .25-1% to help thicken the ink

- Use RV Additive 1-3% to reduce viscosity

Hydrochromic White

Hydrochromic White is a water-reactive foundation that vanishes upon contact with moisture and reemerges once dry.

FEATURES

- Can be printed over a design to conceal it. Once the print is wet the design will appear

- Can be mixed with Neo Pigments to create pastel colors, after cure when color is wet Hydrochromic White disappears leaving color only

- Excellent printability with no viscosity modifications

- Extremely soft hand feel that PVC inks cannot achieve

- Formulated in accordance with the requirements of Oeko-Tex Standard 100, CPSIA and HR4040, but it is not certified.

SPECIAL RECOMMENDATIONS

Can be printed over a design to conceal it. Once the print is wet the design

will appear

Can be mixed with Neo Pigments to create pastel colors, after cure when

color is wet Hydrochromic White disappears leaving color only

Excellent printability with no viscosity modifications

Extremely soft hand feel that PVC inks cannot achieve

OEKO-TEX® Compliant, CPSIA and HR4040 Compliant

- Use Retarder MG 1-5% to help with open time in the screen

- Use Fixer WF-N 1-5% to help with wash fastness

- Use Softener MG 1-4% to help penetrate in to the garment

- Use Thickener B .25-1% to help thicken the ink

- Use RV Additive 1-3% to reduce viscosity

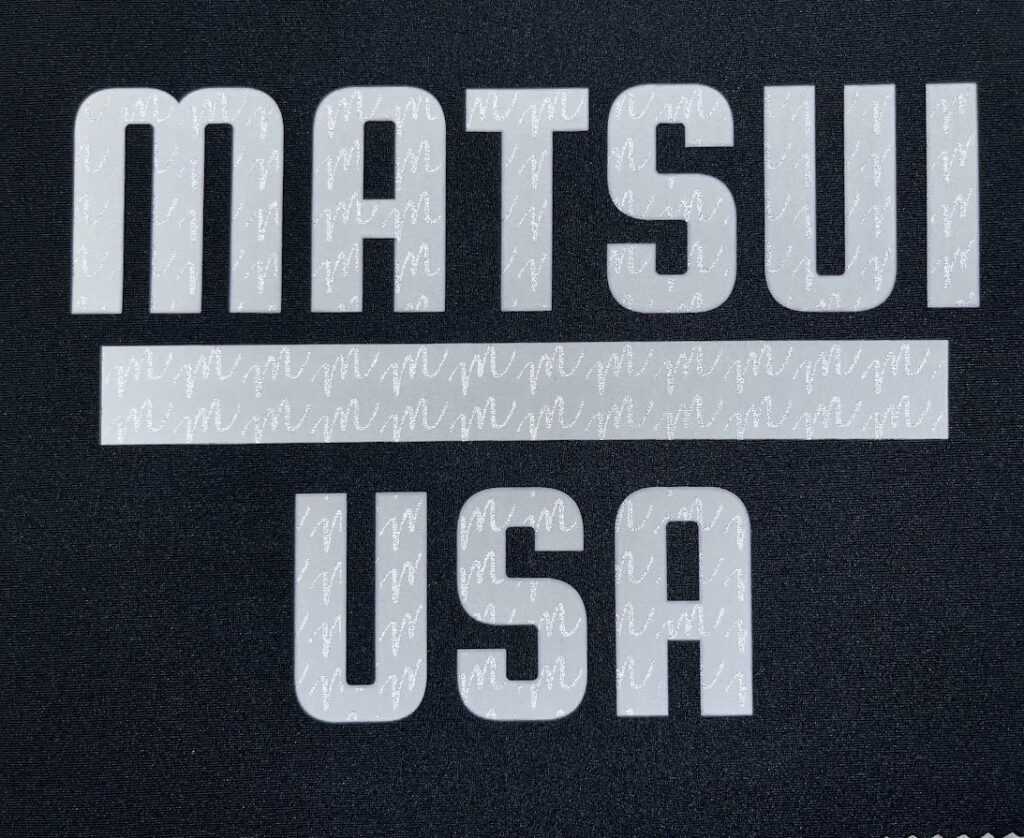

Reflectalite Clear

Reflectalite Clear/Silver Powder

Reflectalite Clear/Silver Powder is a bead-based product incorporated into a base system. The finite and smooth beads effortlessly integrate with ink prints, enhancing the reflective surface with a robust candlepower effect.

FEATURES

- Add up to 40% in to base

- Print must be charged by light to show glow effect

- Excellent printability with no viscosity modifications

- Extremely soft hand feel that PVC inks cannot achieve

SPECIAL RECOMMENDATIONS

Blend Reflectalite in uncontaminated vessels using clean mixing blades and utensils. The introduction of contaminants from other ink sources or unauthorized additives may result in a positive test for restricted PVCs in Reflectalite.

- Use Retarder MG 1-5% to help with open time in the screen

- Use Fixer WF -N 1-5% to help with wash fastness

- Use Softener MG 1-4% to help penetrate into the garment

- Use Thickener B .25-1% to help thicken the ink

- Use RV Additive 1-3% to reduce viscosity

Neonlight

Information

FEATURES

- Information

SPECIAL RECOMMENDATIONS

Information

- Information

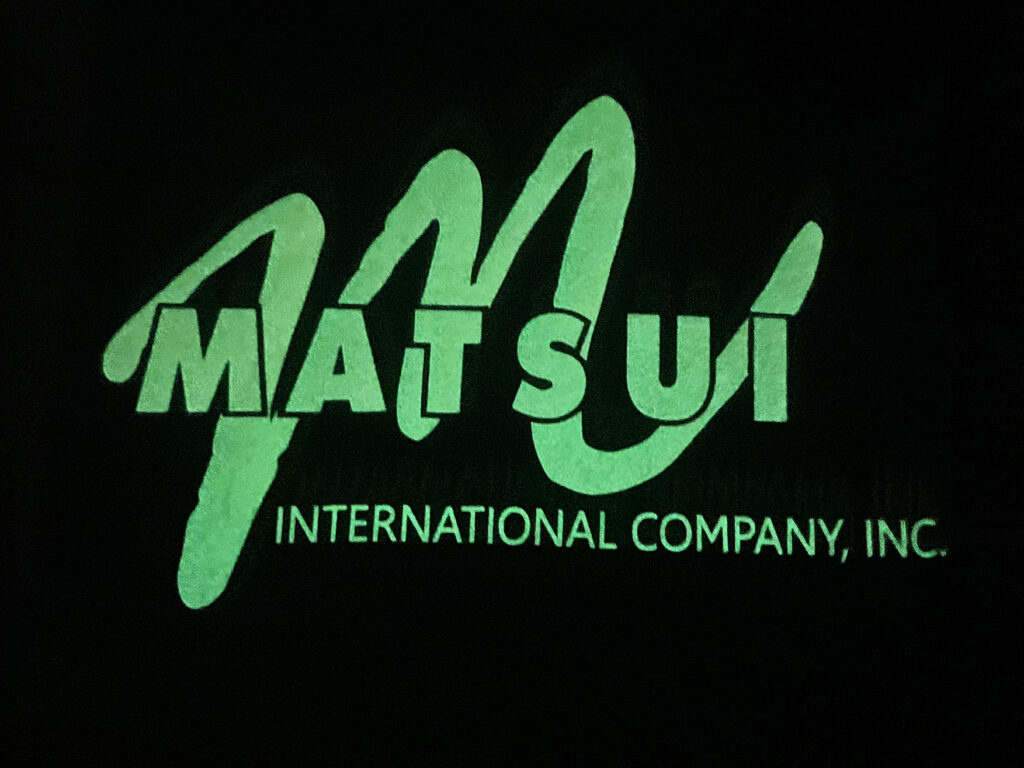

Blacklight

Information

FEATURES

- Information

SPECIAL RECOMMENDATIONS

Information

- Information

Puff

Information

FEATURES

- Information

SPECIAL RECOMMENDATIONS

Information

- Information

Navi

Information

FEATURES

- Information

SPECIAL RECOMMENDATIONS

Information

- Information