Speciality Products :

We thrive on innovation.

For over three decades, we’ve been at the forefront of supplying top-notch thermochromic, photochromic, and Aroma products to customers worldwide. Situated in Japan, Matsui’s cutting-edge R&D department has been a hub for pioneering innovations. Introducing our latest creation, Aqua Indicator, we believe our array of special effects products can elevate your merchandise, making it not just unique but irresistibly compelling.

Color Changing Materials - Photochromic

Photochromic Products

Photopia®

Photopia® is light sensitive pigments that react to Ultraviolet (UV) and sunlight. Colors appear when exposed to UV and sunlight.

PE/PP CONCENTRATE

Photopia® PE/PP Conc is a master batch pellet which is compounded with Photopia Color (light susceptible color change colorant) directly into Polyethylene resin in high concentration. A molded compound with light susceptible color change property can be obtained by diluting 5-10% of the master batch with natural PE/PP Resin and applying injection or extrusion molding. It exhibits color intensely under strong sunlight or ultraviolet radiation, whereas they restore to their original color in the dark and these reversible changes can be repeated again and again.

Photopia® PE/PP Conc are BPA and formaldehyde free products.

AQ INK

Photopia® AQ Ink is a water-based dispersive paste which includes light-sensitive colorants in high concentration. The colorants repeats color changes reversibly through the sunlight or ultraviolet radiation. The print with light-sensitive effect can be obtained through printing the ink mixed with water-based binders. Also, through Aqualite Coloring System, the ink can be used for cotton products.

Photopia® AQ Ink is a BPA and formaldehyde free product.

POWDER

Photopia® color is an organic photochromic colorant which repeats “color exhibition” and “color disappearance” reversibly through the sunlight or ultraviolet radiation. Products with light-sensitive color change effect can be obtained through adding the ink into synthetic resin etc.

Photopia® Color W is colorant which contains stably the light sensitive color change colorant (Photopia Color) into micro capsules. The coatings and printing products exhibit color under sunlight and ultraviolet whereas they restore to their original color in the dark and these reversible changes can be repeated again and again.

Photopia ® Color W can obtain light sensitive color change products without the effect of coating material and additive agent such as vehicle in ink because it contains stably light sensitive color change colorant in micro capsule.

Photopia® Color and Photopia® Color W are BPA and formaldehyde free products.

COLORS

Available Colors

Colors shown and PMS numbers are approximate and may differ from actual colors.

*Color matching provided for special colors

Inside/Without UV

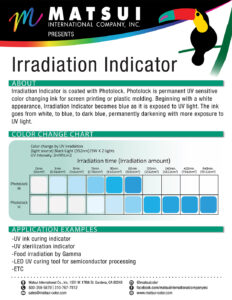

Photolock®

Photolock® is an irreversible UV sensitive color changing ink for screen printing or plastic molding.

AQ INK

Photolock Aqualite Ink (AQ Ink) is the micro-encapsulated irreversible photochromic colorant in waterbased slurry form, behaving from colorless to blue-color changing gradually according to the amount/degree of UV Light.

Compounding Photolock AQ Ink into various aqueous-based clear ink and printing it onto paper, film or fabric, the print with UV indication can be obtained.

The final object printed with Photolock AQ ink changes its color from Colorless >> Blue >> Dark Blue gradually according to the amount/degree of UV Light and will never come back to the Colorless condition. An additional exposure to UV Light even after the blue color starts to occur makes Photolock Blue color further darker according to the accumulated UV Light amount absorbed; therefore, it is ideal to use Photolock for a simple UV-light meter, Sun-Tan warning labels or other indicator purposes.

Types :

- Photolock M— Color change function by minute.

- Photolock H— Color change function by hours.

Usage:

- UV ink curing indicator

- UV sterilization indicator

- Food irradiation by Gamma

- LED UV curing tool for semiconductor processing

- ETC